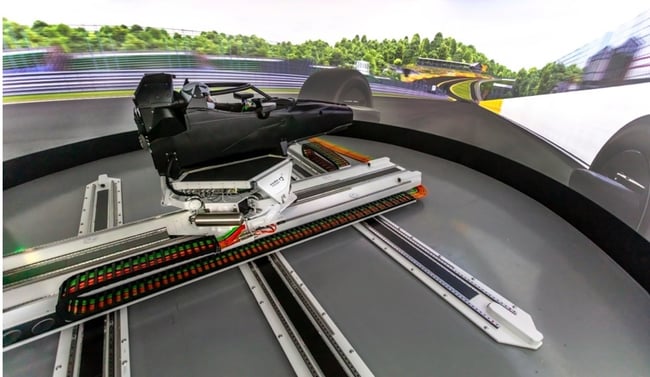

With restricted test days and rising vehicle complexity, Driver-in-the-Loop (DIL) simulators have become a mainstay for proving vehicle development concepts under controlled, repeatable conditions that mirror real racing with more accuracy than ever before – especially when properly correlated.

With restricted test days and rising vehicle complexity, Driver-in-the-Loop (DIL) simulators have become a mainstay for proving vehicle development concepts under controlled, repeatable conditions that mirror real racing with more accuracy than ever before – especially when properly correlated.

Today, the virtual world is where race strategies can be optimised and stress-tested: starts, flying laps and wheel-to-wheel competition can be drilled relentlessly. Multi-driver sessions simulate the realities of interacting with other cars: aerodynamic disturbances, racecraft, tyre management and so on. For hybrids and electric race cars, energy management maps can be tuned for attack or defence, keeping systems within thermal windows across stints.

Conclusive work done behind factory doors in the virtual paddock sets teams in motion, so to speak, for practices, quali sessions and race days. By pre-validating vehicle setups, exploring tire behaviour, mapping energy consumption scenarios and drilling race tactics with multi-driver, multi-sim rehearsals, teams can efficiently convert lab-controlled virtual miles into precious data that informs race weekends. With sim session correlation as the gatekeeper, teams arrive at events with better-understood operating windows, validated strategy options and aligned driver–engineer expectations – thus flipping the script to deliver more answers than questions – which is why race days have increasingly become about informed execution rather than continued experimentation.

Read more in the latest edition of Professional Motorsport World.