Customer race cars are a growing market for major automotive manufacturers. GT3 racing in particular continues to attract new manufacturers. Lexus (RC F), Acura (NSX) and Mercedes-AMG (GT) are joining the competitive IMSA GT Daytona class here in 2017. Ford meanwhile is the latest company to join GT4 competition on both sides of the Atlantic, having unveiled the Mustang GT4 at the SEMA show in November.

OEMs have long used racing to promote their brands, but on-track success is not the only way that racing now contributes to the bottom line. Savvy manufacturers can generate direct income (in addition to indirect sales income) by building and selling customer cars for motorsport use. Following its post-Dieselgate decision to end its works WRC program, for example, Volkswagen has confirmed that it will build and sell an R5-spec Polo for customer rally competition, and perhaps even rent existing Polo WRCs to interested teams.

Balanced Performance

In GT racing, FIA Balance of Performance (BOP) regulations help to level the playing field for all competitors. This encourages vehicle constructors and race teams alike to compete, knowing that any successes will be the result of learning to extract the most from the car. But as in any form of racing, everybody is still looking for that ever-elusive competitive edge.

In such a technological arms race – one that is contained within the hardware, calendar, and other boundaries set forth by regulations – team resources and energies are often directed towards simulation and vehicle preparation methodologies, and any other tools that better the chances for race day readiness. For example, many OEMs are using new-generation realistic racing simulators to develop the chassis and aerodynamic packages for their customer competition cars.

Racing simulators – or engineering class Driver-in-the-Loop (DIL) simulators, to be more exact – are ideal tools for OEM-perspective design and development challenges since they provide endless hours of virtual seat time to confirm fundamental design directions, sort out tuning packages, and gather valuable feedback from test drivers. OEMs know that their customer cars must be fast and forgiving in the hands of different teams, who often engage amateur drivers rather than seasoned professionals. And most importantly - a certain confidence level needs to be achieved regarding competitiveness within BOP envelopes before the vehicles are produced and released into the wild. If your badge is going to be on the car's nose, the car better be good!

Teamwork

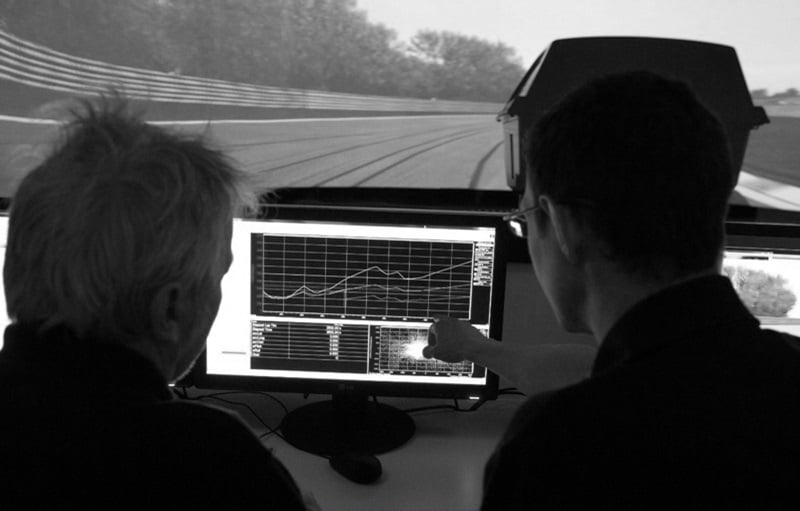

Once customer cars reach the teams, on-track test time will typically be restricted by the race series. In addition, drivers may have other business commitments that limit their ability to travel to tests even when the opportunity exists. In both cases, access to a capable DIL simulator laboratory provides a flexible, cost-effective alternative to physical seat time, with the added bonuses of facilitating positive, personal working relationships between drivers and race engineers, and providing ways to explore driver and vehicle limits in a safe lab environment where bodies and bodywork are never at risk.

Customer race teams themselves might be lucky enough to have simulator time at an OEM’s R&D facility to become more familiar with their car, explore setups, and prepare drivers and race engineers for competition. But whether the team and drivers use an OEM’s DIL simulator, their own simulator, or rent virtual test driving time at a third-party facility, there are considerable advantages to be had from “testing” their vehicle in a sim lab – assuming the simulator is capable of delivering a realistic experience.

Different vehicle setups, different tires, and even different weather and track conditions can all be simulated, "driven" in a virtual sense. And as we discussed in a previous article, one secret benefit of accumulating DIL simulator seat time has to do with the vehicle development and race day preparation that can take place in a rather unconventional way. For example, focusing on specific track segments can be quite a bit easier, enabling the refinement of corner entry/exit techniques that can have a large payoff in terms of lap times and overall competitiveness. But even in the case of real world replica test sessions, any time spent in a driving simulator lab is usually considered to be time well spent!

Download our FREE motorsport eBook to read more about new approaches in race preparation, vehicle/driver development strategies, and the capabilities of realistic racing simulators: