Traditionally, subjective evaluation of steering system performance has required the use of real test vehicles on real proving grounds. This stands to reason because the tactile feedback of a steering wheel is such an important part of the subjective driving experience, and historically speaking, the simulation of steering feeling has been one of the most challenging performance tasks for driving simulators.

Steering system performance evaluations (objective and subjective) are typically focused on the broad categories of steering effort, response, and linearity. Each category has its own nuances. And in plain terms, it is no small task to command an electric motor (in a driving simulator) to deliver representative handwheel torque from vehicle, tire, and road surface models in order to convey such nuances.

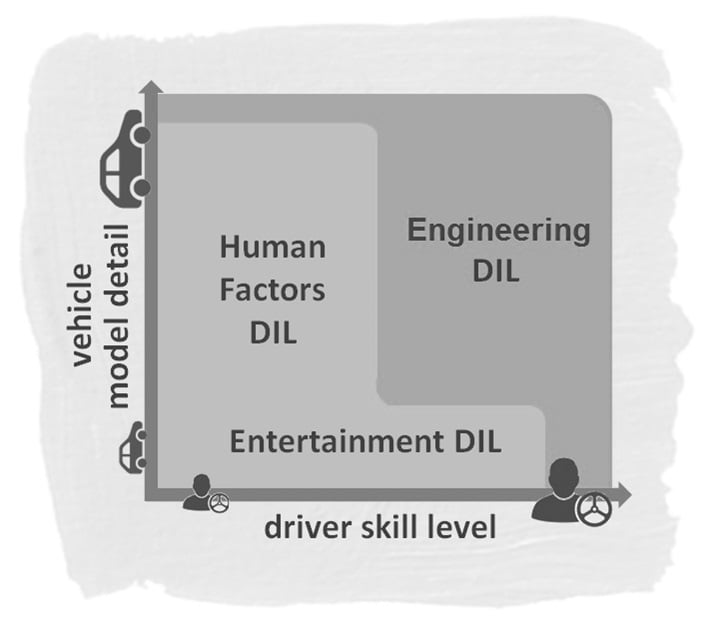

Until recently, Driver-in-the-Loop (DIL) simulators have lacked the computational and motor control capabilities that would enable drivers to receive informative, realistic handwheel feedback from complex real time models.

Placing Real Drivers Back into the Equation

Interestingly, a next-generation vehicle dynamics class driving simulator architecture has been introduced that is ideal for Driver-in-the-Loop evaluations of complex subsystems such as steering systems. This approach immerses drivers into compelling environments that can capture the key characteristics of the vehicle, road surface, suspension, tires and on-board electronic control systems. In so doing, it brings real people back into direct contact with the complex modelling which has been relegated to off-line simulation in recent years.

The architecture allows real-time sensory feedback that is free from the latencies and motor cogging issues that can inhibit the subjective perceptions of an expert driver. With sufficiently descriptive vehicle and environment models, the driver’s brain can accept the illusion of controlling a real car using a real steering system due to the fidelity of the sensory feedback.

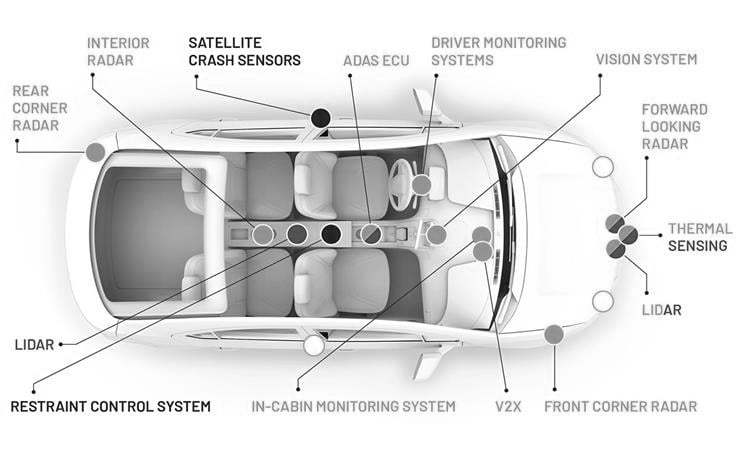

This next-generation technology features several key elements that enable vehicle steering systems to be accurately modelled and evaluated using a DIL simulator:

Highly Responsive Motion Systems

• Handwheel torque feedback system that can be perfectly synchronized with other driver feedback cues. This requires ultra-low system latency (the time delay between vehicle dynamics demand and motor flux generation) plus motor control technology that can balance high peak torque capability (such as that required for failsafe testing) with excellent sensitivity (such as that required for on-center response evaluations). Such a system, Ansible Motion’s HWLS, is shown here.

• Vestibular feedback systems that do not induce motion sickness, such as the stratiform motion system that is used for ground vehicle simulation.

• Haptic feedback systems that are layered appropriately in a complimentary fashion, such that tactile nuances are delivered without disrupting primary feedback cues.

High Performance Computer Systems

• Tire and road surface models must be executed in real time, and must be of sufficient fidelity to inform a steering system model of force vectoring.

• Vehicle physics models must be executed in real time, and must be of sufficient fidelity to provide appropriate demand signals to motion and feedback systems. Within the steering sub-system model alone there are mechanical and electrical system modeling challenges. For example, Electric Power Assisted Steering (EPAS) systems may require Hardware-in-the-Loop (HIL) connectivity. Additional modelling challenges are introduced when vehicle manufacturers and steering system suppliers work together in a co-development capacity.

• Synchronicity and Efficiency of execution is required amongst the various DIL simulator applications, so the executive (hosting) environment must be robust and flexible.

As the primary control device for the car and a major contributor to a car’s overall character, the steering system, more than any other, requires accurate and reliable subjective evaluation. If such subjective evaluation can occur via DIL simulation, vehicle manufacturers have a powerful tool for exploring more variations in less time, safely, and at earlier stages in the development process.

As with any “simulated system,” all the modelled tuning parameters are adjustable, and all the measurement details are readily obtained. But adding a real driver into the mix is the key, since it elevates simulations to function as subjective feedback tools – and this is not just practical, it is necessary.

To learn more about how to improve vehicle sub-system development programs with driving simulators, download our FREE eBook, Looking down the road: Harnessing the benefits of driving simulator technology: